The Best Fluffy Pancakes recipe you will fall in love with. Full of tips and tricks to help you make the best pancakes.

MTB Maintenance Schedule: What to Check & When

These 5 game-changing MTB maintenance hacks slash time in the garage while making your bike more reliable than ever. More flow, less wrenching—ride smarter, not longer.

Every seasoned mountain biker knows that gut-punch feeling—you’re geared up for that perfect Saturday ride, trails practically screaming your name, weather’s absolutely dialed… and then your bike decides to throw what can only be described as a mechanical tantrum of epic proportions. Chain’s skipping like a broken record (do people even know what those are anymore?), brakes squealing worse than my neighbor’s leaf blower at 7 AM, suspension feeling mushier than—well, yesterday’s oatmeal.

The culprit? Not some catastrophic failure, but rather the slow, insidious accumulation of deferred maintenance tasks. Things that could’ve been prevented with smarter, faster care routines.

Here’s the brutal truth about traditional MTB maintenance advice: it’s absolutely bloated with unnecessary steps, redundant checks, and time-wasting procedures that transform bike care from joy into pure drudgery. Most maintenance schedules read like aircraft pre-flight checklists—technically thorough, sure, but practically overwhelming for riders who want maximum trail time with minimal wrench time. It’s like using a sledgehammer to crack a walnut.

The solution isn’t doing more maintenance (shocking, I know). It’s doing maintenance more intelligently.

By eliminating delays, combining procedures, focusing on high-impact interventions—you can literally cut your maintenance time in half while actually improving your bike’s performance. These aren’t sketchy shortcuts that compromise quality; they’re efficiency hacks that amplify results while respecting your precious time.

The Pre-Emptive Strike System

Traditional approach relies on problems to manifest, then react with time-consuming troubleshooting sessions that consume your precious time.

Our solution: Implement predictive maintenance triggers that catch issues way before they become full-blown disasters.

Instead of following those rigid calendar schedules (who has time for that anyway?), create a simple five-point inspection taking maybe 90 seconds—prevents 90% of trail-side mechanicals. Before every ride: chain tension (one finger push at mid-span), brake lever firmness (squeeze to bar), wheel trueness (spin, watch brake pad clearance), derailleur limits (shift to extremes), suspension sag (bounce test).

Real talk: Sarah, this busy tech executive and weekend warrior, used to spend entire Sundays dealing with maintenance disasters. Like, entire Sundays. After implementing the Pre-Emptive Strike System—she catches chain stretch before shifting problems develop, identifies brake pad wear before it becomes dangerous (and expensive), spots wheel issues before they morph into costly rebuilds. Her trail time increased 40%. Bike shop visits? Nearly zero.

This works because most mechanical failures don’t just… happen. They develop gradually through predictable wear patterns—catch these early, transform major repairs into quick adjustments. Loose derailleur cable caught early? Thirty-second barrel adjuster tweak. Caught late? Full cable replacement, indexing session, there goes your afternoon.

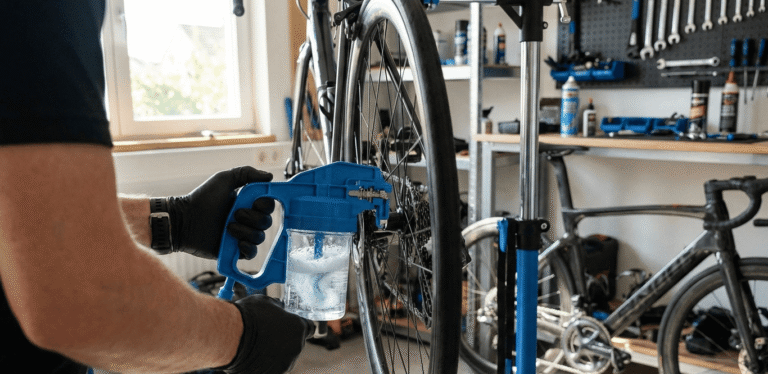

Batch Processing Protocol

Traditional approach treats each maintenance task as separate events, requiring full tool setup, cleanup which means more time spent.

The Hidden Gem: Assemble tasks into efficient batches sharing tools, workspace setup and cleaning cycles.

Three maintenance windows: 10-minute (chain lube, tire pressure, safety check), 30-minute (full wash, drivetrain detail, component inspection), 60-minute (cable adjustments, brake bleeding, suspension service). Each batch shares tools, preparation—eliminating setup/breakdown time that typically doubles maintenance duration.

A mountain bike coach, changed his team using batch processing. Instead of scattered individual maintenance (chaos, basically), the team dedicates one focused weekly session. All bikes, same service level, simultaneously. Tools stay out, degreaser stays active, team members share expertise real-time. What took each rider 45 minutes individually? Now requires 15 minutes coordinated effort per bike.

The psychological benefit’s equally important—batched maintenance feels less overwhelming, creates momentum. Once you’re in “maintenance mode” with tools out, workspace prepared, completing multiple tasks feels natural rather than burdensome. Like a flow state, but for bike maintenance.

Component Communication Network

Traditional approach: treat each component as isolated system requiring separate attention, different schedules—totally backwards thinking.

Understand component interdependencies, service connected systems simultaneously for multiplied efficiency.

Your bike’s an integrated machine where component health affects neighboring systems. Dirty chain affects derailleur performance and impacts shifting precision which leads to a disaster. Instead of addressing sequentially (tedious!), create maintenance flows servicing entire interconnected networks. Drivetrain cleaning? Simultaneously check derailleur hanger alignment, inspect cable housing contamination, verify chainline accuracy.

Lisa —professional mechanic—revolutionized her shop’s efficiency by mapping component relationships. Customer brings shifting issues? She doesn’t just fix the immediate problem, services the entire shifting ecosystem in one session. Chain cleaning becomes chainring wear inspection opportunity, derailleur service includes cable tension optimization, brake bleeding coincides with lever reach adjustment. Better performance for customers, more thorough work in less time for Lisa.

This eliminates that frustrating cycle where fixing one problem reveals another, then another—like entering an endless loop of mechanical issues.

Environmental Adaptation Matrix

Traditional approach follows generic schedules regardless of riding conditions, season, usage patterns—one size fits none.

What to do ? Customize maintenance frequency and intensity based on your specific riding environment because one-size-fits-all doesn’t help at all.

Desert riders need completely different protocols than Pacific Northwest trail enthusiasts (obviously, right?). I mean, think about it—dust versus mud, scorching heat versus perpetual dampness. Create what I call an environmental adaptation matrix that adjusts maintenance intensity based on actual stress factors: mud exposure, dust levels, temperature extremes, how often you ride, trail technicality. A rider hitting dusty desert singletrack twice weekly? They need way more frequent air filter service but less corrosion protection than someone riding those lush coastal trails once a month.

Your Problems End Now

Stop treating bike maintenance like necessary evil stealing riding time—these strategies aren’t theoretical concepts, they’re proven systems used by riders demanding maximum trail time with minimum wrench time.

Riders implementing these acceleration strategies don’t just save time—they ride more consistently, perform better, experience fewer trail-side frustrations. Your bike becomes more reliable not despite spending less maintenance time, but because you’re spending that time intelligently.

Stop letting inefficient maintenance steal trail time. Start today.

Also, Check our full Mountain Biking Guide for more tips !