The Best Fluffy Pancakes recipe you will fall in love with. Full of tips and tricks to help you make the best pancakes.

Look, most mountain bikers—and I mean the vast majority of us, myself included for years—spend our precious riding time doing mountain bike maintenance the absolutely hard way. We meticulously follow every single traditional step we’ve seen in those YouTube videos (you know the ones, where the guy has like 47 specialized tools hanging on a pegboard). Also scrub every component until it literally gleams like it just rolled off the factory floor, and we’ll consult three, maybe four different tutorials before we even THINK about touching our drivetrain.

We disassemble more than we probably should. Second-guess our work constantly. Turn what should be a 20-minute job into this two-hour ordeal that just… eats into weekend ride time. And then we wonder why we never have time to actually ride.

Why do we overcomplicate things like this?

Because—and hear me out—the internet has basically convinced us that proper bike maintenance requires this monk-like patience, right? A garage that looks like a Park Tool catalog exploded in it, and the technical precision of a Swiss watchmaker (or maybe a neurosurgeon, take your pick). We’ve been conditioned, almost programmed really, to believe that shortcuts equal negligence. That faster methods somehow compromise quality. That real mechanics never, ever cut corners.

But here’s the truth that professional mechanics don’t always share with you: many of these elaborate processes we’ve adopted? They’re unnecessary holdovers from different eras of bicycle technology or—and this is key—simply inefficient traditions that nobody has bothered to question. Like, at all.

The most effective maintenance isn’t always the most time-consuming. Sometimes it’s actually the opposite.

After interviewing veteran bike shop mechanics (the ones who’ve been doing this since cantilever brakes were still a thing), enduro racers who wrench their own bikes between stages because they have to, and gear engineers who actually design the components we’re all riding—a pattern emerged. The riders who keep their bikes running flawlessly? They aren’t the ones spending hours in the garage every weekend. They’re the ones who’ve identified the high-impact maintenance tasks that actually, genuinely matter… and developed intelligent shortcuts to execute them efficiently.

Let me share three game-changing shortcuts that will revolutionize your maintenance routine. These are backed by real mechanics and riders who’ve proven their effectiveness over thousands of miles down the trail, through mud and dust and everything in between.

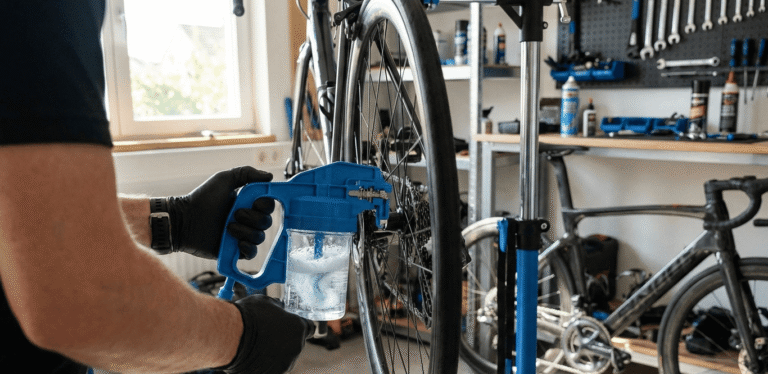

How to Clean Your Mountain Bike Chain in 3 Minutes: The Wet Wipe Method

The Long Road: Traditional chain cleaning involves—brace yourself—removing your chain (which means you need a chain tool and need to remember which way the quick link goes), soaking it in degreaser that smells like industrial waste, scrubbing it with brushes, running it through one of those chain cleaning devices that inevitably leaks, rinsing, drying completely (which takes forever), and THEN re-lubricating. Total time: 45-60 minutes, easy. The process creates a mess that would make your significant other question your life choices, requires multiple products, and honestly? Most riders avoid it until their drivetrain sounds like a bag of rusty nails being thrown down a staircase.

The Shortcut: Keep a pack of automotive wet wipes in your garage. Or baby wipes work too—don’t overthink it. After every muddy or dusty ride, just hold a folded wipe around your chain and backpedal 20-30 revolutions. Apply fresh lube to the clean chain.

Total time: 3 minutes. Maybe 4 if you’re being thorough.

Why It Works: Here’s what most riders don’t understand, and it took me years to figure this out—your chain doesn’t need to be surgically clean. Like, at all. The enemy isn’t surface dirt; it’s that abrasive grit that works its way into the rollers and between the plates, grinding everything down molecule by molecule. Research from friction testing labs (and yes, these exist) shows that a chain cleaned to remove 80% of contamination performs nearly identically to a chain cleaned to 100% perfection.

The wet wipe method achieves that critical 80% threshold by removing the contaminated surface lube that’s holding grit—while the fresh lube you apply afterward? It actually flushes out interior particles during your first few minutes of riding. It’s brilliant in its simplicity.

Real-World Impact: Sarah Chen, an enduro racer up in British Columbia (where the mud is basically sentient), switched to this method two seasons ago. “I was replacing chains every 300 miles with the traditional deep-cleaning method—which I did maybe once a month because it was such a production,” she explains over coffee at a bike festival last spring. “With the wet wipe approach after every ride, my chains now last 800-1,000 miles. The consistency matters way more than the intensity.”

The mathematics are actually pretty compelling when you sit down and work it out. If you ride twice weekly (which is probably conservative for most of us who are obsessed), the traditional method might happen twice monthly. Optimistically. That’s 8 cleanings over four months. The wet wipe method would give you 32 cleanings in the same period—four times the maintenance frequency with LESS total time invested.

Your drivetrain responds to frequency, not perfection. Remember that.

Mountain Bike Suspension Service: When to Actually Service Your Fork and Shock

The Long Road: Most riders religiously follow manufacturer service intervals like they’re the Ten Commandments—50 hours for lower leg service, 125 hours for a full damper service, tracked meticulously in a maintenance log that lives in their phone or on a spreadsheet. They schedule shop appointments weeks in advance (because good mechanics are always booked), pay $150-300 for services, and often service forks and shocks that are… still performing perfectly? It’s madness when you think about it.

The Shortcut: Ignore the hour counts. Just—ignore them. Instead, perform the “drop test” monthly. Compress your fork or shock through its full travel and release it. It should return smoothly and relatively quickly, with no weird stiction or hesitation. If the return feels sluggish or you notice any hesitation (you’ll feel it, trust me), THEN service the lower legs. For rear shocks, if you can’t achieve full travel on your normal trails anymore, service time has arrived.

Why It Works: Hour-based service intervals are conservative estimates designed to prevent failures under worst-case conditions. We’re talking riders in Scottish mud (which is like riding through wet concrete), dusty Arizona deserts where the sand is basically microscopic sandpaper, or coastal salt spray that corrodes everything it touches. If you ride in moderate conditions and store your bike properly—not in a shed where temperature swings 40 degrees daily—your suspension can often run 2-3 times longer than published intervals without any performance degradation.

The financial math is straightforward, but the performance benefit is subtle and significant in ways that are hard to quantify. Freshly serviced suspension often needs 2-3 rides to break in, during which performance isn’t optimal. It’s still good, but not great. By servicing based on need rather than schedule, you’re more often riding on suspension at peak performance.

Bike Bolt Torque Settings: Which Bolts Actually Need a Torque Wrench

The Long Road: Conscientious riders torque every single bolt to manufacturer specifications using a torque wrench, checking multiple times per season. They carry torque specs in their phone (there’s probably an app for it), reference them constantly, and spend collective hours—hours!—ensuring every stem bolt, seatpost clamp, and brake caliper is precisely at specification. Down to the Newton-meter.

The Shortcut: Identify your bike’s six critical torque points. Just six: stem bolts, handlebar clamp, seatpost clamp, brake rotor bolts, cassette lockring, and suspension linkage pivots. Only these require torque wrench precision. Everything else? Can be tightened by feel following the “snug plus a quarter turn” rule.

That’s it.

Why It Works: Not all bolts are created equal—this should be obvious but somehow isn’t. The six critical points listed above directly affect safety (stem, bars, brakes) or expensive component integrity (cassette, rotors, pivots). These deserve torque wrench attention because the consequences of getting them wrong are… significant. But bolts holding cable guides? Derailleur adjustment screws? Bottle cages? Dozens of other components? They have massive safety margins. Over-torquing these is nearly impossible by hand unless you’re using a breaker bar. (which, please don’t), and under-torquing reveals itself through rattling or looseness you’ll notice immediately on your first ride.

“We torque maybe 10% of the bolts on a bike in a professional shop environment.” Admits Amy Nakamura, a master mechanic at a high-volume bike shop in Portland. “Once you understand what ‘snug plus a quarter turn’ feels like. And it doesn’t take long to learn—you’re within tolerance on 95% of non-critical fasteners.”

The quarter-turn rule is brilliantly simple, almost stupidly so: tighten until the bolt stops moving easily (snug), then add one-quarter rotation. This consistently lands you in the safe zone for standard M4, M5, and M6 bolts that are common on bicycles. It’s the Goldilocks approach—not too tight, not too loose.

Real-World Impact: David Park, a cross-country racer who maintains bikes for his entire team (talk about pressure), implemented strategic torquing this season. “Previously, a complete bike check took 90 minutes because I’d torque everything with my wrench. Now it takes 25 minutes—I hit the six critical points with the torque wrench and everything else by feel. We haven’t had a single failure, and I’ve personally checked over 40 bikes this way.”

The time savings compound in ways that are honestly shocking. If you’re checking bolts monthly—which you should be, especially if you’re riding hard—that’s 60 minutes saved per year. An hour you could spend riding instead of rotating a wrench in your garage while your bike sits on a stand.

Why Consistent Mountain Bike Maintenance Beats Perfect Maintenance Every Time

These shortcuts share a common philosophy, a thread that runs through all of them: focus intensity where it matters most. The wet wipe method prioritizes frequency over depth. The drop test prioritizes performance over rigid adherence to schedules. Strategic torquing prioritizes safety-critical components over completionist perfectionism (which is really just anxiety dressed up as diligence).

When combined—and here’s where it gets interesting—these three shortcuts can reduce your annual maintenance time by 40-50% while actually improving your bike’s performance and longevity. You’re not cutting corners in the bad way. You’re cutting waste.

Consider the typical rider who attempts comprehensive maintenance: they spend 3-4 hours monthly on elaborate cleaning, follow rigid service schedules like their life depends on it, and meticulously torque every bolt on the bike. That’s 36-48 hours annually. Nearly two full days of your life, spent in the garage.

The rider using these shortcuts? They invest 90 seconds after each ride on chain cleaning, perform quarterly suspension checks (takes 5 minutes), and do focused bolt checks monthly. Total annual time: 20-25 hours. The shortcut rider spends half the time and typically experiences better performance because—and this bears repeating—consistency trumps intensity every single time.

Your Next Ride Starts in the Garage (But It Doesn’t Have to End There)

The mountain bike maintenance game isn’t won by those who follow every tradition without question, like some kind of mechanical orthodoxy. It’s won by riders who understand which tasks deliver disproportionate value and execute them consistently. Not perfectly—consistently.

Stop letting maintenance steal your riding time. I’m serious about this—life’s too short to spend it degreasing chains for an hour when you could be on the trail.

Start with one shortcut this weekend. The wet wipe chain cleaning is the easiest entry point, requires almost zero investment (you probably have wipes already), and delivers immediate results. After your next ride, spend three minutes wiping down your chain instead of skipping cleaning entirely because the “proper” method feels overwhelming and you’re tired and just want to shower.

Notice how much smoother your drivetrain feels on your next ride. It’s immediate.

Then add the drop test to your monthly routine—set a reminder in your phone if you need to. Compress, release, observe. Let your suspension tell you when it needs attention instead of consulting a spreadsheet or trying to remember when you last serviced it.

Finally, mark your six critical torque points with a silver marker (or whatever color you have). The next time you’re checking your bike, pull out your torque wrench for just those six points. Tighten everything else by confident feel, trusting that you’re not going to strip a bolt by hand.

These aren’t shortcuts around maintenance—they’re shortcuts through the inefficiency that keeps most riders from maintaining their bikes consistently. And consistency, not perfection (I’ll say it again because it matters), is what keeps you on the trail instead of at the bike shop explaining to a 19-year-old mechanic what’s making that weird clicking sound.

Your bike doesn’t need a perfectionist. It needs a rider who shows up consistently with focused effort in the right places. Be that rider.

Your trails are waiting, and honestly? They don’t care how clean your chain is—they just want you to show up. Learn More About Mountain Biking .