The Best Fluffy Pancakes recipe you will fall in love with. Full of tips and tricks to help you make the best pancakes.

Choosing the Best MTB Brakes: Hydraulic vs Mechanical

A breakdown of braking systems and what suits each riding style.

Brakes are one of the most critical components on any mountain bike, directly influencing safety, control, and rider confidence. For beginners and experienced riders alike, the decision often comes down to hydraulic vs mechanical MTB brakes.

Hydraulic brakes deliver powerful, precise stopping performance ideal for technical terrain, while mechanical brakes provide budget-friendly simplicity that’s easy to maintain on the trail. In this guide, we’ll compare performance, maintenance, durability, cost, and weather handling so you can choose the right brakes for your riding style.

For a broader overview of gear, techniques, and upgrades, check out our complete Mountain Biking Guide.

Braking Power and Control Performance

Mountain biking brake performance dramatically impacts your safety and riding confidence on challenging terrain. Hydraulic MTB brakes deliver superior stopping power through pressurized fluid systems. Mechanical brakes rely on cable tension for adequate but less precise control.

| Brake Type | Stopping Power | Modulation | Best For |

| Hydraulic MTB Brakes | Excellent | Precise control | Technical trails, steep descents |

| Mechanical MTB Brakes | Good | Basic control | Casual riding, beginner trails |

Hydraulic brake advantages:

- Stronger clamping force creates shorter stopping distances on steep descents

- Excellent modulation allows precise control over braking intensity levels

- Consistent performance maintains reliability during long technical mountain biking sessions

- Less finger effort required for powerful stopping compared to mechanical systems

Mechanical brake characteristics:

- Adequate stopping power for most recreational mountain biking applications

- Less precise modulation makes fine-tuned control more challenging

- Requires more hand strength for equivalent stopping power

- Performance varies based on cable tension and adjustment quality

Performance impact on riding:

- Hydraulic systems inspire confidence on technical descents and challenging trails

- Mechanical brakes work well for cross-country and less demanding mountain biking

Choosing appropriate MTB brakes significantly affects your trail riding experience and safety.

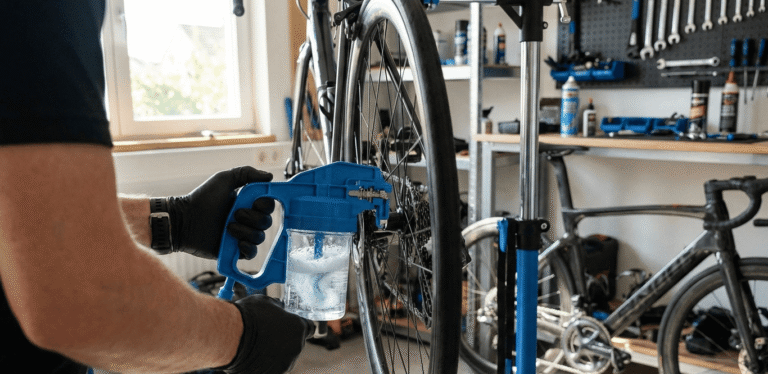

Maintenance Requirements and Complexity

MTB brake maintenance varies significantly between hydraulic and mechanical systems for riders. Understanding service requirements helps choose brakes matching your mechanical skills and preferences. Both systems require regular attention but demand different approaches and tools.

Hydraulic MTB brake maintenance:

- Periodic bleeding removes air bubbles from the fluid system annually

- Self-adjusting pads compensate for wear automatically during mountain biking sessions

- Requires specialized tools and knowledge for proper brake fluid bleeding

- Professional service recommended for complex hydraulic system repairs

Mechanical brake maintenance:

- Simple cable adjustments using basic tools most riders already own

- Manual pad adjustment needed as components wear during mountain biking

- Cable replacement necessary when cables stretch or develop fraying

- Easy troubleshooting and repair possible on trails during rides

| Maintenance Aspect | Hydraulic | Mechanical |

| Complexity | High | Low |

| Required Tools | Specialized | Basic |

| Frequency | Annual bleeding | Regular adjustments |

| DIY Friendly | No | Yes |

Beginner considerations:

- Mechanical systems offer learning opportunities for basic bike maintenance

- Hydraulic brakes provide consistent performance with less frequent attention

Long-term costs:

- Professional hydraulic brake service costs more than mechanical maintenance

- Mechanical systems allow budget-friendly home maintenance for mountain biking enthusiasts

Choose MTB brakes matching your comfort level with bicycle maintenance tasks.

Durability and Reliability in Trail Conditions

Mountain biking brake durability determines long-term performance across various trail conditions and weather. Both hydraulic and mechanical MTB brakes offer distinct reliability characteristics. Understanding failure modes helps select appropriate brakes for your riding environment.

Hydraulic brake durability factors:

- Sealed systems resist contamination from dirt and debris during rides

- Hydraulic lines can leak if damaged by rocks or crashes

- Consistent performance across temperature variations and long descents

- More complex system means potential for specialized component failures

Mechanical brake reliability:

- Simple cable systems resist catastrophic failure modes during mountain biking

- Cables can stretch, fray, or rust over time with exposure

- Performance affected by housing contamination and cable friction buildup

- Easy field repairs using basic tools on remote trails

| Reliability Factor | Hydraulic | Mechanical |

| Weather Resistance | Excellent | Good |

| Impact Damage Risk | Moderate | Low |

| Field Repair Difficulty | High | Low |

| Catastrophic Failure Risk | Low | Very low |

Environmental considerations:

- Wet and muddy conditions favor hydraulic MTB brake performance

- Desert and dusty environments may challenge both systems differently

- Cold weather affects hydraulic fluid viscosity and mechanical cable flexibility

Backup planning:

- Mechanical brakes allow trail-side repairs with minimal tools

- Hydraulic systems typically require shop visits for major issues

Component longevity:

- Quality hydraulic brakes last many seasons with proper maintenance

- Mechanical brake cables need replacement more frequently than hydraulic components

Select MTB brakes based on your typical riding conditions and reliability priorities.

Weight and Cost Considerations

MTB brake weight and cost significantly influence bike setup decisions for different riding styles. Budget constraints often determine brake choice for new mountain biking enthusiasts. Performance benefits must balance against financial and weight penalties for each system.

Cost comparison factors:

- Entry-level mechanical MTB brakes start around $30-50 per wheel

- Basic hydraulic mountain biking brakes begin at $80-120 per wheel

- High-end hydraulic systems can exceed $200-300 per wheel setup

- Long-term maintenance costs favor mechanical systems for budget riders

Weight differences:

- Quality hydraulic brakes typically weigh less than mechanical equivalents

- Cable routing adds weight compared to hydraulic line systems

- Lever design affects overall system weight for mountain biking setups

- Weight savings matter more for competitive cross-country riders

Value considerations:

- Mechanical brakes offer excellent value for recreational mountain biking

- Hydraulic systems justify costs through superior performance and convenience

- Upgrade path allows starting mechanical and switching later

- Used hydraulic brake markets provide budget-friendly performance options

Budget planning tips:

- Consider mechanical brakes for first mountain bike purchases

- Save hydraulic upgrades for when skills demand better performance

- Factor maintenance costs into total ownership expenses

- Quality mechanical brakes outperform cheap hydraulic systems

Performance per dollar:

- Mechanical systems maximize stopping power per budget dollar spent

- Hydraulic brakes deliver premium performance for serious mountain biking

Choose MTB brakes balancing your budget constraints with performance requirements effectively.

Weather Performance and Real-World Applications

Mountain biking brake performance varies dramatically across different weather and trail conditions. Wet, muddy, and dusty environments challenge braking systems in unique ways. Understanding these performance differences guides appropriate MTB brake selection for local conditions.

Wet weather performance:

- Hydraulic MTB brakes maintain consistent power through rain and mud

- Sealed hydraulic systems resist water contamination during mountain biking sessions

- Mechanical cables can bind when water infiltrates housing systems

- Pad compound affects wet weather performance for both brake types

Muddy trail conditions:

- Hydraulic brakes clear debris more effectively with stronger clamping force

- Self-adjusting hydraulic pads compensate for contamination automatically during rides

- Mechanical systems require manual adjustment after muddy mountain biking adventures

- Cable stretch increases in harsh conditions affecting mechanical brake feel

Dusty and dry conditions:

- Both systems perform well in dry mountain biking environments

- Dust infiltration affects cable housing performance over time

- Hydraulic seals prevent contamination in sandy or dusty conditions

- Regular cleaning maintains optimal performance for both brake types

Real-world application recommendations:

- Choose hydraulic brakes for all-weather mountain biking and technical terrain

- Select mechanical systems for fair-weather riding and budget considerations

- Consider local climate when making MTB brake decisions

- Match brake choice to typical trail conditions and riding frequency

Seasonal considerations:

- Winter riding favors hydraulic systems for consistent performance

- Summer trail maintenance easier with mechanical brake simplicity

Select MTB brakes matching your typical riding conditions and weather exposure patterns.